The Manufacturer’s Preventive Maintenance Checklist

Limiting Unplanned Downtime

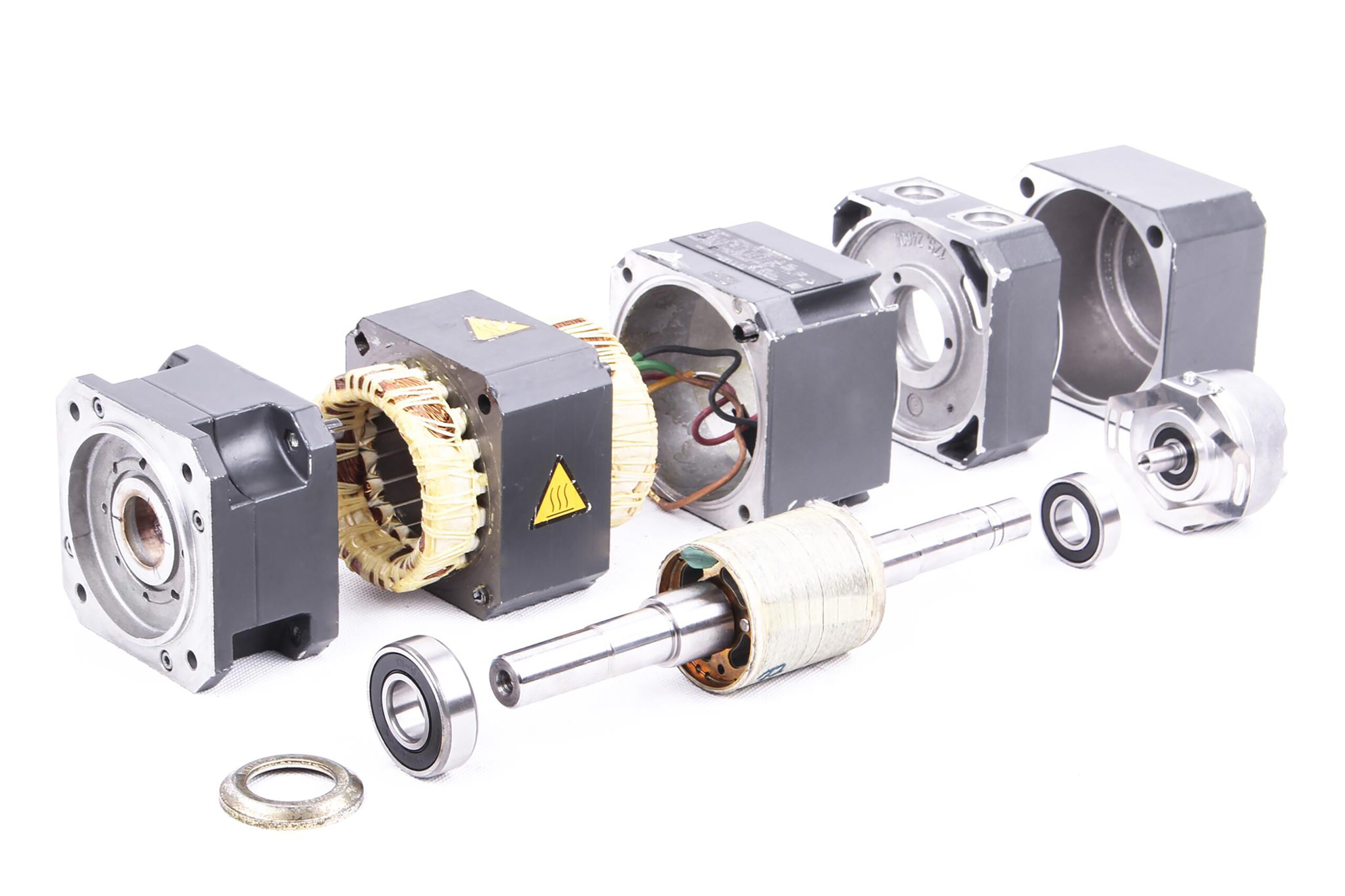

A well-executed preventive maintenance program is key to maximizing efficiency, enhancing reliability, and extending equipment lifespan. For servo motor-powered machinery, regular inspection and servicing are essential to maintain peak performance. To minimize risks and reduce costly disruptions, preventive maintenance should include servo motors. This approach ensures continuous operation, boosting reliability, improving efficiency, and driving greater profitability. Scroll down to access the guide.

Causes of Equipment Downtime

Servo motor-driven equipment failures often result from wear and tear, electrical issues, overheating, or contamination. Additional factors that extend downtime include:

- Poorly scheduled maintenance

- Lack of trained personnel

- Insufficient spare parts inventory

- Inability to accurately diagnose issues

Financial & Operational Consequences

A recent Forbes article, Unplanned Downtime Costs More Than You Think reveals that 82% of manufacturers have faced at least one unplanned downtime incident in the past three years. Many of these disruptions stem from inefficient maintenance practices, low technician productivity, and a reliance on contractors. While well-run facilities spend around $100 million annually, low-efficiency plants can see costs soar to $400 million. On average, manufacturers experience 800 hours of downtime per year, translating to a staggering $50 billion in annual industry losses.What You'll Get From the Guide:

Why Preventive Maintenance is Critical

Understand the benefits of preventive maintenance, including reduced downtime, lower maintenance costs, increased productivity, less scrap, and more.

How to Build a Preventive Maintenance Process that Works

Get insights into the equipment you'll need on site, how often specific components should undergo maintenance, when to send out for repair, and more.

A Useful Preventive Maintenance Checklist

Find value in a handy, all-in-one checklist that ensures that you're following maintenances tasks, such as critical inspections, lubrication, calibration, and part replacements.

Access The Checklist

Download the The Manufacturer’s Preventive Maintenance Checklist

About Mitchell Electronics, Inc.

Since 1979 Mitchell Electronics, Inc. has been serving the motion control industry. For over two decades we have been providing encoder and servo motor test equipment for use in the field of repair and plant maintenance. We continue to respond to market needs for innovative products that include rapid and comprehensive support and training.

More Servo Resources

9 Steps to Reduce Servo Motor Repair Costs

5 Mistakes to Avoid with Servo Motor Maintenance and Repair

The Hidden Costs of Intermittent Servo Motor Failures

Copyright © 2024 Mitchell Electronics, Inc.