TI-5260-PSP

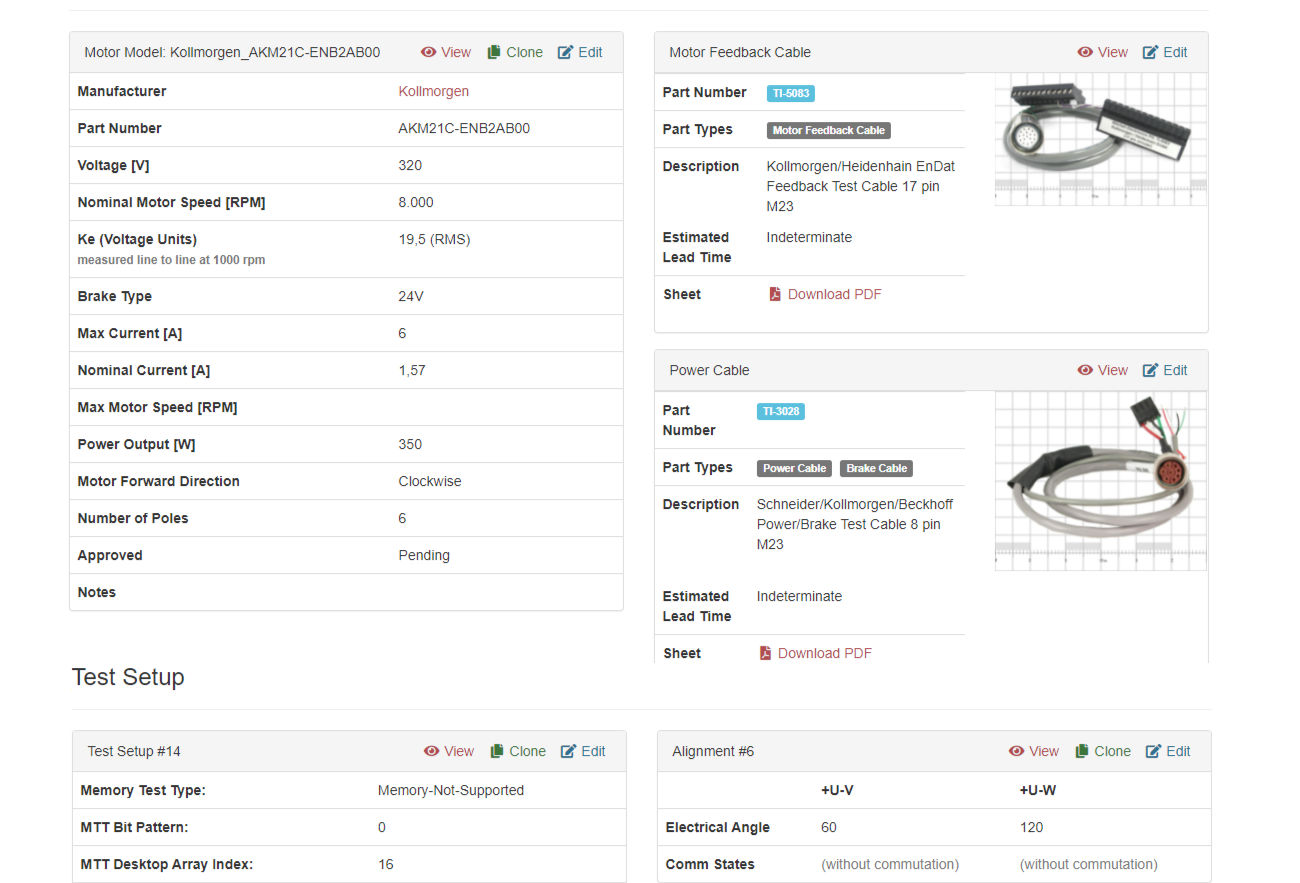

The TI-5260-PSP Permanent Magnet Servo Motor Rotor Lockup System provides a simple and accurate method of applying the correct current to the correct set of windings to lock up a permanent magnet brushless AC or DC servo motor. Rotor locking is an effective method to determine the forward armature direction of the servo motor. Rotor locking is used to check the alignment angle of the servo motor feedback device. It is also used when adjusting the feedback electrical angle to obtain the proper servo motor alignment. This electrical alignment angle is either specified by the servo motor manufacturer or stored in the memory contents of the encoder feedback device. This information is often readily available in the Bobcat online database. The TI-5260-PSP phase switches are wired and labeled to allow application of a positive polarity, negative polarity, or open circuit to each of the servo motor phases. You can apply any polarity to create any line to line or line to neutral lockup. In absence of a TI-5260-PSP lockup system product, users may be tempted to constantly swap wires to obtain various servo motor rotor lockup positions. However, this procedure is error prone, and incorrect connections are a common cause of incorrect feedback alignment during servo motor repair. Labeled switches make the connection much simpler and quicker for the servo technician and also improve safety and reliability. Multiple lockup positions can be set and verified very quickly which provides valuable double checks of the encoder alignment angle, resulting in higher quality during the servo motor repair process.