SERVO MOTOR REPAIR PRODUCTS

Solve Your Servo Headaches

When servos go off-line for unscheduled maintenance or repairs, manufacturers take a hit on production, quality, and profitability.

While these issues aren’t 100% preventable, there’s a lot you can do to lessen the impact of machine downtime. That’s why we put together these two helpful guides:

- The Quick Reference Guide to Servo Motor Maintenance and Repair.

- The Manufacturer’s Preventive Maintenance Checklist

Inside these in-depth guides, you’ll find insights into: diagnosing common servo issues, understanding common servo error codes, and practicing preventive maintenance that reduces downtime and improves the bottom line.

Products

Where Servo Motor Testers are Used

Our products are used in the following environments:

About Mitchell Electronics

Our Servo

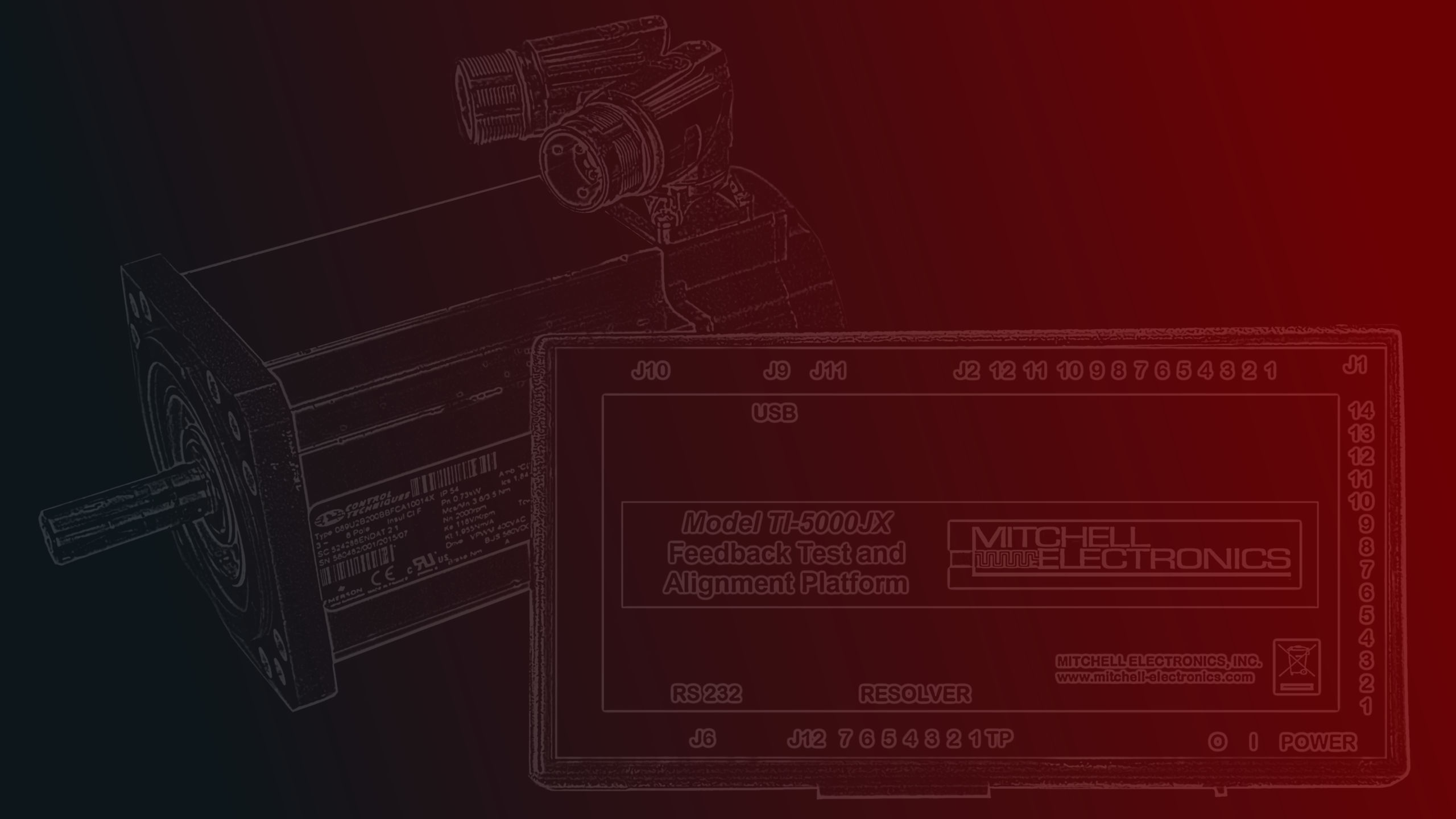

Motor Test Solutions

Since 1979 Mitchell Electronics, Inc. has been serving the motion control industry. For over two decades we have been providing encoder and servo motor test equipment for use in the field of repair and plant maintenance. We continue to respond to market needs for innovative products that include rapid and comprehensive support and training.

Read More

Mitchell Electronics

About us

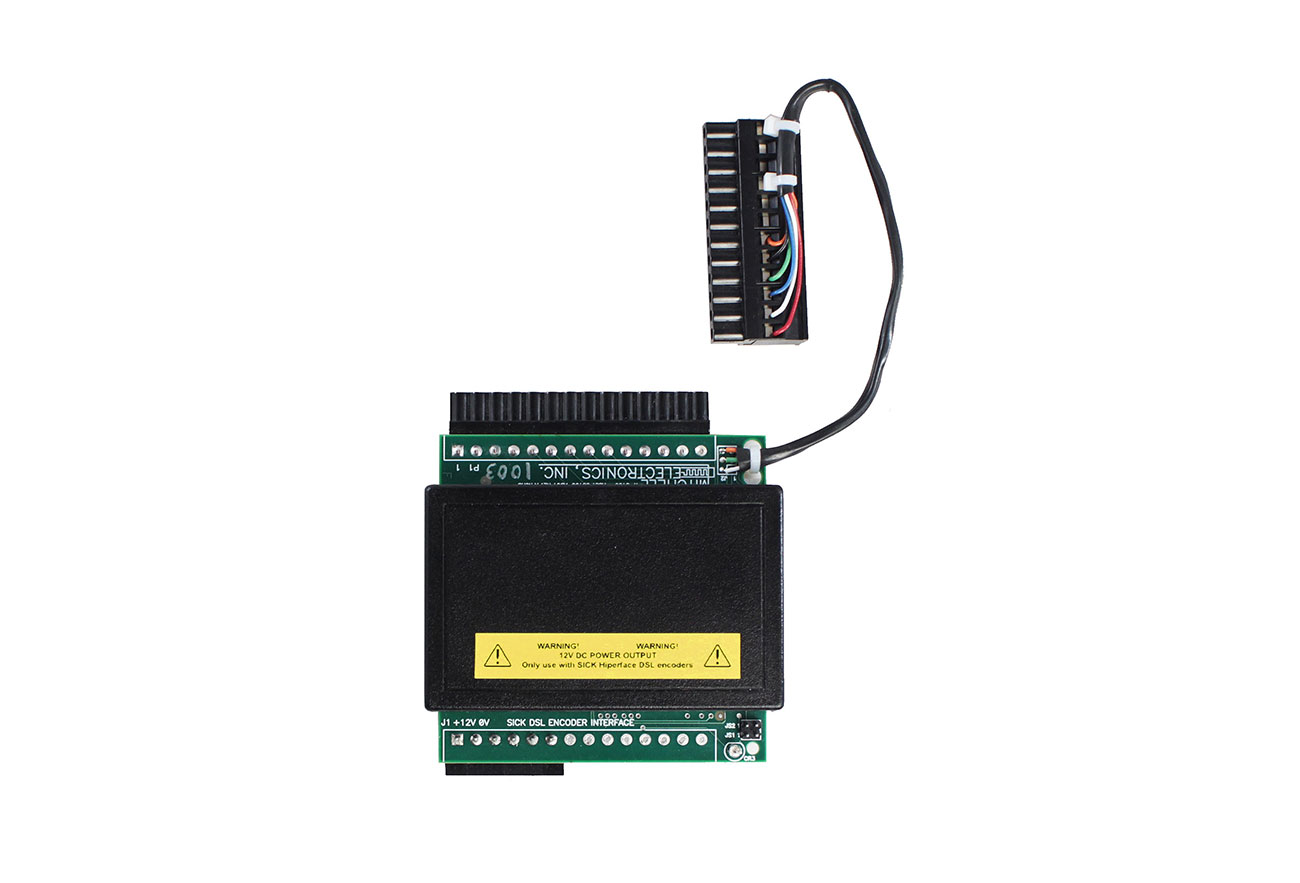

Mitchell Electronics, Inc. has been designing and manufacturing products for the motion control industry since 1979. We offer servo motor and feedback solutions for customers working with permanent magnet brushless AC or DC servo motors, incremental encoders, serial encoders, and resolvers. Our products are used for repairing servo motors, offering encoder diagnostic and alignment capability. Customers interact through the Athena Windows PC software application and the Bobcat online servo motor information database.

New features are added continuously, such as the Fanuc “Alpha i” serial High-Speed protocol mode, SICK Stegmann Hiperface DSL, Heidenhain EnDat, BiSS, and Mitsubishi HG. Legacy styles such as Yaskawa C Channel Encoders, and hall effect sensors and tachometers, as seen on Baumuller servo motors are also supported. We also offer personalized product support and training, as this is essential for saving time and improving quality. Training sessions can be brief, spontaneous, and customized to the skills and learning ability of each individual. Talk to us to learn how to avoid down time, or costly repair errors.